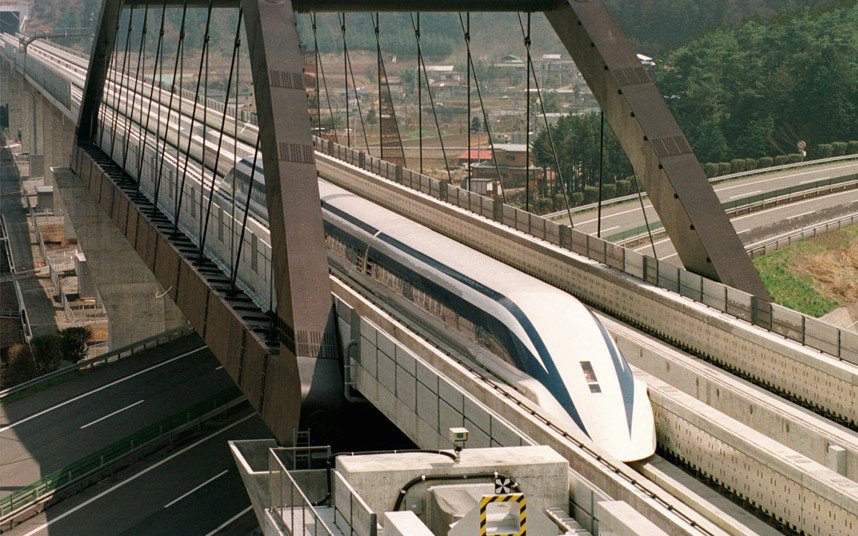

Maglev train in Japan

Maglev (derived from magnetic levitation) is a system of train transportation that uses two sets of magnets, one set to repel and push the train up off the track, and another set to move the elevated train ahead, taking advantage of the lack of friction. Along certain “medium-range” routes (usually 320 to 640 km [200 to 400 mi]), maglev can compete favorably with high-speed rail and airplanes.

With maglev technology there is just one moving part: the train itself. The train travels along a guideway of magnets which control the train’s stability and speed. Propulsion and levitation require no moving parts. This in stark contrast to electric multiple units that may have several dozen parts per bogie. Maglev trains are therefore quieter and smoother than conventional trains, and have the potential for much higher speeds.

Maglev vehicles have set several speed records and maglev trains can accelerate and decelerate much faster than conventional trains; the only practical limitation is the safety and comfort of the passengers. The power needed for levitation is typically not a large percentage of the overall energy consumption of a high-speed maglev system.Overcoming drag, which makes all land transport more energy intensive at higher speeds, takes the most energy. Vactraintechnology has been proposed as a means to overcome this limitation. Maglev systems have been much more expensive to construct than conventional train systems, although the simpler construction of maglev vehicles makes them cheaper to manufacture and maintain.

The Shanghai maglev train, also known as the Shanghai Transrapid, has a top speed of 430 km/h (270 mph). The line is the fastest and currently the first and only, commercially successful, operational high-speed maglev train, designed to connect Shanghai Pudong International Airport and the outskirts of central Pudong, Shanghai. It covers a distance of 30.5 km (19 mi) in 7 or 8 minutes. For the first time, the launch generated wide public interest and media attention, propelling the popularity of the mode of transportation.Despite over a century of research and development, currently high-speed maglev is only available in China and maglev transport systems are now operational in just three countries (Japan, South Korea and China). The incremental benefits of maglev technology have often been considered hard to justify against cost and risk, especially where there is an existing or proposed conventional high-speed train line with spare passenger carrying capacity, as in high-speed rail in Europe, the High Speed 2 in the UK and Shinkansen in Japan.

In the late 1940s, the British electrical engineer Eric Laithwaite, a professor at Imperial College London, developed the first full-size working model of the linear induction motor. He became professor of heavy electrical engineering at Imperial College in 1964, where he continued his successful development of the linear motor.Since linear motors do not require physical contact between the vehicle and guideway, they became a common fixture on advanced transportation systems in the 1960s and ’70s. Laithwaite joined one such project, the Tracked Hovercraft, although the project was cancelled in 1973.

The linear motor was naturally suited to use with maglev systems as well. In the early 1970s, Laithwaite discovered a new arrangement of magnets, the magnetic river, that allowed a single linear motor to produce both lift and forward thrust, allowing a maglev system to be built with a single set of magnets. Working at the British Rail Research Division in Derby, along with teams at several civil engineering firms, the “transverse-flux” system was developed into a working system.

The first commercial maglev people moverwas simply called “MAGLEV” and officially opened in 1984 near Birmingham, England. It operated on an elevated 600 m (2,000 ft) section of monorail track between Birmingham Airport and Birmingham International railway station, running at speeds up to 42 km/h (26 mph). The system was closed in 1995 due to reliability problems.

In the public imagination, “maglev” often evokes the concept of an elevated monorailtrack with a linear motor. Maglev systems may be monorail or dual rail—the SCMaglevMLX01 for instance uses a trench-like track—and not all monorail trains are maglevs. Some railway transport systems incorporate linear motors but use electromagnetism only for propulsion, without levitating the vehicle. Such trains have wheels and are not maglevs.Maglev tracks, monorail or not, can also be constructed at grade or underground in tunnels. Conversely, non-maglev tracks, monorail or not, can be elevated or underground too. Some maglev trains do incorporate wheels and function like linear motor-propelled wheeled vehicles at slower speeds but levitate at higher speeds. This is typically the case with electrodynamic suspension maglev trains. Aerodynamicfactors may also play a role in the levitation of such trains.

MLX01 Maglev train Superconducting magnetbogie

The two main types of maglev technology are:

- Electromagnetic suspension (EMS), electronically controlled electromagnets in the train attract it to a magnetically conductive (usually steel) track.

- Electrodynamic suspension (EDS) uses superconducting electromagnets or strong permanent magnets that create a magnetic field, which induces currents in nearby metallic conductors when there is relative movement, which pushes and pulls the train towards the designed levitation position on the guide way.

Electromagnetic suspension (EMS)

Electromagnetic suspension (EMS) is used to levitate the Transrapid on the track, so that the train can be faster than wheeled mass transit systems

In electromagnetic suspension (EMS) systems, the train levitates above a steel rail while electromagnets, attached to the train, are oriented toward the rail from below. The system is typically arranged on a series of C-shaped arms, with the upper portion of the arm attached to the vehicle, and the lower inside edge containing the magnets. The rail is situated inside the C, between the upper and lower edges.

Magnetic attraction varies inversely with the square of distance, so minor changes in distance between the magnets and the rail produce greatly varying forces. These changes in force are dynamically unstable—a slight divergence from the optimum position tends to grow, requiring sophisticated feedback systems to maintain a constant distance from the track, (approximately 15 mm (0.59 in)).

The major advantage to suspended maglev systems is that they work at all speeds, unlike electrodynamic systems, which only work at a minimum speed of about 30 km/h (19 mph). This eliminates the need for a separate low-speed suspension system, and can simplify track layout. On the downside, the dynamic instability demands fine track tolerances, which can offset this advantage. Eric Laithwaite was concerned that to meet required tolerances, the gap between magnets and rail would have to be increased to the point where the magnets would be unreasonably large.In practice, this problem was addressed through improved feedback systems, which support the required tolerances.

Electrodynamic suspension (EDS)

The Japanese SCMaglev’s EDS suspension is powered by the magnetic fields induced either side of the vehicle by the passage of the vehicle’s superconducting magnets.

EDS Maglev propulsion via propulsion coils

In electrodynamic suspension (EDS), both the guideway and the train exert a magnetic field, and the train is levitated by the repulsive and attractive force between these magnetic fields. In some configurations, the train can be levitated only by repulsive force. In the early stages of maglev development at the Miyazaki test track, a purely repulsive system was used instead of the later repulsive and attractive EDS system.The magnetic field is produced either by superconducting magnets (as in JR–Maglev) or by an array of permanent magnets (as in Inductrack). The repulsive and attractive force in the track is created by an induced magnetic field in wires or other conducting strips in the track.

A major advantage of EDS maglev systems is that they are dynamically stable—changes in distance between the track and the magnets creates strong forces to return the system to its original position. In addition, the attractive force varies in the opposite manner, providing the same adjustment effects. No active feedback control is needed.

However, at slow speeds, the current induced in these coils and the resultant magnetic flux is not large enough to levitate the train. For this reason, the train must have wheels or some other form of landing gear to support the train until it reaches take-off speed. Since a train may stop at any location, due to equipment problems for instance, the entire track must be able to support both low- and high-speed operation.

Another downside is that the EDS system naturally creates a field in the track in front and to the rear of the lift magnets, which acts against the magnets and creates magnetic drag. This is generally only a concern at low speeds, and is one of the reasons why JR abandoned a purely repulsive system and adopted the sidewall levitation system. At higher speeds other modes of drag dominate.

The drag force can be used to the electrodynamic system’s advantage, however, as it creates a varying force in the rails that can be used as a reactionary system to drive the train, without the need for a separate reaction plate, as in most linear motor systems. Laithwaite led development of such “traverse-flux” systems at his Imperial College laboratory.Alternatively, propulsion coils on the guideway are used to exert a force on the magnets in the train and make the train move forward. The propulsion coils that exert a force on the train are effectively a linear motor: an alternating current through the coils generates a continuously varying magnetic field that moves forward along the track. The frequency of the alternating current is synchronized to match the speed of the train. The offset between the field exerted by magnets on the train and the applied field creates a force moving the train forward.

Tracks

The term “maglev” refers not only to the vehicles, but to the railway system as well, specifically designed for magnetic levitation and propulsion. All operational implementations of maglev technology make minimal use of wheeled train technology and are not compatible with conventional rail tracks. Because they cannot share existing infrastructure, maglev systems must be designed as standalone systems. The SPM maglev system is inter-operable with steel rail tracks and would permit maglev vehicles and conventional trains to operate on the same tracks. MAN in Germany also designed a maglev system that worked with conventional rails, but it was never fully developed.

Article by Naveen s , pc10 , 20191CSE0377

Nice

LikeLiked by 1 person

Tq

LikeLike

Tq

LikeLike

Nice blog

LikeLiked by 1 person

Tq

LikeLike

Nice

LikeLiked by 1 person

Tq

LikeLike

Thank you

LikeLike